Technical Informations / Installation Procedure

In the sewerage systems, there is an unpressurized free flow. But they are installed under ground; they are subject to external loads. Therefore, effects of external loads such as earth and traffic load become prominent. Triplex pipes are designed to have strength against this type of loads. In the sewerage systems, there are some installation rules that must be complied with in the underground pipe applications.

In the sewerage systems, there is an unpressurized free flow. But they are installed under ground; they are subject to external loads. Therefore, effects of external loads such as earth and traffic load become prominent. Triplex pipes are designed to have strength against this type of loads. In the sewerage systems, there are some installation rules that must be complied with in the underground pipe applications.

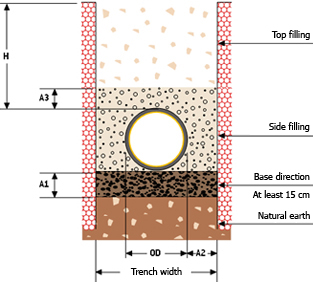

In order to maintain Triplex pipe and fittings serve for longer years without problem, in the under ground applications requiring a channel digging, layer-by-layer compression must be done around the pipes while filling the channel so as not to leave weak zones. In particular filling the bottom of pipe with filling material is very important. If the filling process is carried out with strong compression according to specifications, then the traffic and earth load on the pipe will be conveyed to filling in partial, as a result pipe functions its duty during its service life without any problem. Due to gaps arising improper compression, pipe cannot transfer the load to other forces, so a collapse risk may occur.

- Base direction: Must be 15 cm and compressed minimum at a rate of %95.

- Side filling width: Must be A2=50 cm.

- Side filling: Must be once every 30 cm and compressed minimum at a rate of %95.

- Top filling: Must be minimum 30 cm and normal compression must be made.

- Material: 0-Materials with 20 mm diameter coarse and compressible containing 20% humid.

- Height above pipe: Must be minimum 50 cm.