TIG Pipes are used for warm and cold water systems, radiator systems, pressured air installations, transmission of cooled fluids, inner-building fresh water systems and floor heating systems. TIG Pipes are produced through a special technology combining the superior features of plastic and metal materials. While the inner and outer layers of TIG Pipes are made of polyethylene, aluminum is used for the production of the middle layer.

The name of this special pipe is derived from the special method used to produce it. Aluminum layer is twisted over the polyethylene layer (its molecule structure includes cross linked PE-Xb) and these two materials are then fixed with arc welding (Tungsten Inert Gas).

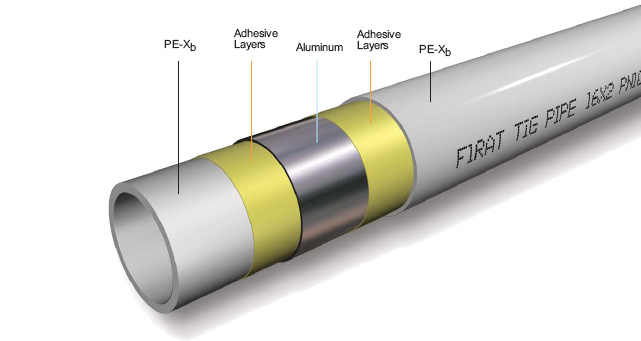

Inner and outer surfaces of TIG Pipes are formed by PE-Xb layers which are resistant to high temperatures, hygienic,, resistant to corrosion and impacts taking root of external influences, very smooth and which are preventing sedimentation, providing excellent isolation.

In addition to these, a special adhesive and method is used for fixing the inner and outer PE-Xb layers with excellent properties to the aluminum layer.