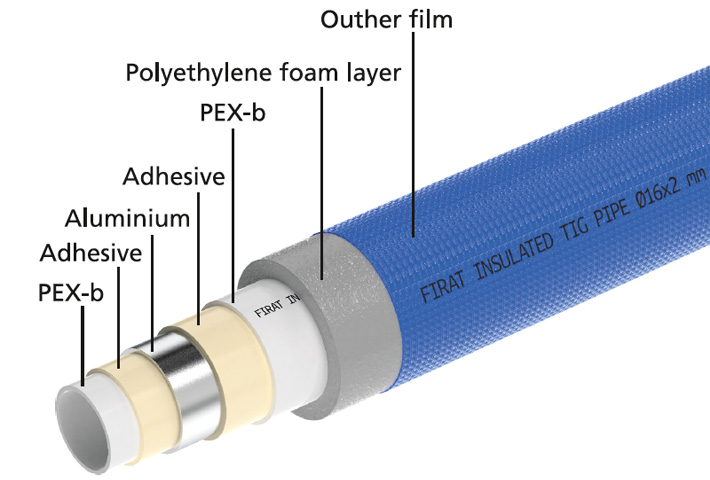

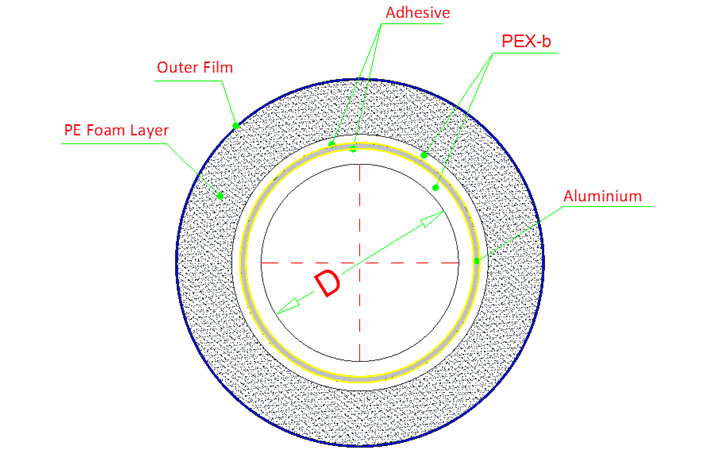

Pipes with insulation coating consist of an inner and outer surfaces of TIG Pipes are formed by PE-Xb layers which are resistant to high temperatures, hygienic, resistant to corrosion and impacts taking root of external influences, very smooth and which are preventing sedimentation, providing excellent isolation. In addition to these, a special adhesive and method is used for fixing the inner and outer PE-Xb layers with excellent properties to the aluminum layer.

The insulation coating, made with polyethylene foam, enhances the system energy efficiency and further reduces the noise transmission.

The insulation section consists of a polyethylene foam layer protected by a special outer film - red or blue for heating and cooling systems.

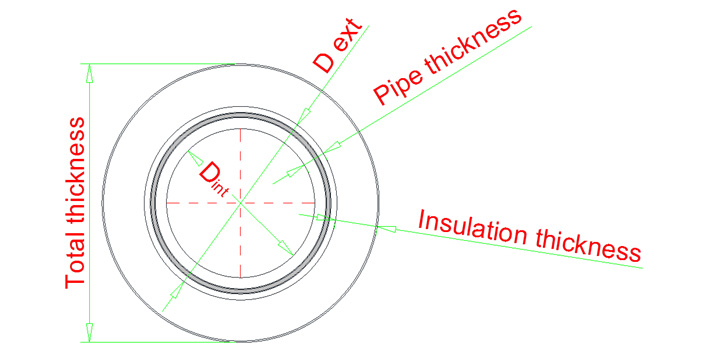

The technical characteristics of the insulation PEX/AL/PEX pipes are as follows:

- Application classes (EN ISO 21003-1): 1, 2

- Fire classification: B-s1-d1 (EN 13501-1)

- Thickness (round) : 6 or 10 mm

- Maximum operating temperature 95ºC

- Operating conditions for hot applications 95ºC 10 bar

- Density at 23 °C: 0,30 g/cm3 (polyethylene foam)

- Thermal expansion coefficient: 0,025 mm/m0 K

- Thermal conductivity: 0,40 W/m0 K

- Surface roughness: 0,006 mm

- Softening temperature: 135 °C

- Permeability to oxygen: 0 mg/l

- Cross-linking method : PEX b (silane)

- Welding method for aluminum: Tig welding (Tungsten Inert Glass)

| CODE | D(mm) | d(mm) | t(mm) | T(mm) | L (coil/m) |

|---|---|---|---|---|---|

| 7497006116M | 16 | 16 | 2 | 6 | 100 |

| 7497010116M | 16 | 16 | 2 | 10 | |

| 7497006118M | 18 | 18 | 2 | 6 | 100 |

| 7497010118M | 18 | 18 | 2 | 10 | |

| 7497006120M | 20 | 20 | 2 | 6 | 100 |

| 7497010120M | 20 | 20 | 2 | 10 | |

| 7497006126M | 26 | 26 | 3 | 6 | 50 |

| 7497010126M | 26 | 26 | 3 | 10 | |

| 7497006132M | 32 | 32 | 3 | 6 | 50 |

| 7497010132M | 32 | 32 | 3 | 10 |