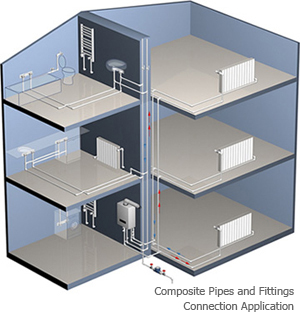

Fırat Composite Pipe and Fittings produced with combination of PP-R (Polypropylene Random Copolymer) raw material and fiber glass reinforced polypropylene raw materials is an indispensable solution in today’s indoor hot and cold water systems with its advantages such as smooth and bright internal surface, calcification and rust-free, hygienic and easy to mount. Used in any kind of indoor hot and cold water pipe systems, Fırat Composite Pipe and Fittings are produced from the Type-3 class raw material, also called as PP-R (Polypropylene Random Copolymer).

ADVANTAGES OF FIRAT COMPOSITE PIPE

- Since Fırat fiber glass reinforced PP-R pipes have a thermal expansion co-efficient close to foiled pipes, they can conveniently be used in the areas where foiled pipes are used.

For Fiber Glass Reinforced PP-R: 0,040 mm/mK

For Foiled Pipe: 0,030 mm/mK

- The welding of the Fırat fiber glass reinforced PP-R pipes are just like plain pipe, does not require shaving.

- Once Fırat fiber glass reinforced PP-R pipe does not require shaving, it is applied 30% faster than foiled pipes.

Model Application

- Ø 20 mm diameter fiber glass PP-R and Foiled PP-R pipes are compared.

- Comparison is conducted under Laboratory conditions

- The calculation refers to an apartment pipe systems with 300 welding application.

| Welding duration of one fibre glass reinforced PP-R pipe | 20,8 sec |

| Welding duration of one foiled PP-R pipe | 30,3 sec |

| Time-saving with Fiber glass reinforced PP-R pipe welding | 9,5 sec |

| Total time saving for 300 welds | 47,5 dk |

- Systems where Fırat fiber glass reinforced PP-R pipe heating and chilling is used together do not pose perspiration and stretching problems.

- Heat loses caused by aluminum in the foiled pipes do not occur in the Fırat fiber glass reinforced PP-R pipes.

Aluminum heat transfer co-efficient: 190 W/mK

Fiber Glass heat transfer co-efficient: 1,10 W/mk

When internal and external surfaces are controlled with bare eyes instead of a magnifier, they must be smooth, clean, not cracked, not bubbled and not porous. Material should not pose visible impurities. Pipe tips must be cut perpendicular to clean pipe axis.

Fırat Compoiste Pipe and Fittings are particularly designed for the systems with cold and hot water transfer. Middle layer with high insulation feature used in the Composite Pipe and Fittings prevent pipe to be expanded and sagged.

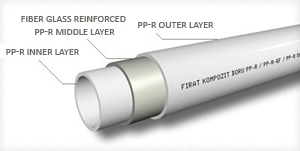

Fırat Composite Pipe and Fittings is a pressurized pipe system used for indoor cold and hot water systems. It has a multi-layered structure. Middle layer is made up of fiber glass reinforced PP-R (Polypropylene random copolymer) and inner and outer layer of PP-R raw material. Service Class is 1/10 bar pipe group. It is designed to function for 50 years under 20 bar pressure at 20°C.

When used under proper pressure and temperature values, the life of Composite Pipe and Fittings is more than 50 years.

- Its useful life is 50 years under 20 bar pressure at 20°C.

- It is suitable to use between -20 °C and +90°C. (Insulation must be applied by taking the freezing point of the fluid in the pipe into account)

- It is under B2 class according to DIN 4102 standard.

- Perspiration and stretching does not pose problem in the systems where composite pipe heating and cooling used together.

- It has high resistance against chemical substances.

- It is corrosion resistant. Also it is calcification and rust-free.

- Has smooth and bright internal surfaces.

- No diameter contraction in the welding points. Has high welding performance.

- Since no shaving is required for composite pipes, it enables fast assembly opportunity.

- Applicable in the surface mounted areas with its aesthetic appearance.

- Environment-friendly.

- No assembly loss.