Assembly

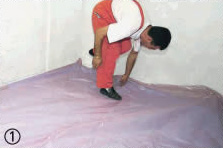

Over the clean and straightened base, insulation material which provides sound and heat insulation between layers is laid down and then it is coated with polyethylene folio (1). According to installation project, Fıratpex pipes are mounted with the help of plates and collector connection is made (2). Plates with clips are mounted according to installation project (3). Upon conducting tightness test, system becomes ready for grout. Grout concrete must be at a thickness of minimum 3.5 cm over the Fıratpex pipes and dilatation must be done (4).

TESTING FIRATPEX PIPING SYSTEM

Before covering the installation which is mounted, operation, pressure and impermeability test must certainly be conducted. Water should be supplied into system with a hand-operated pump and a manometer that will enable observation of desired pressure value from test pump should be attached.

For Pressure test;

1. All points that are open in installation which is tested must be closed.

2. All valves in the installation must be turned off.

3. System must be filled with water at the lowest point of piping system and main valve must be opened slightly. In order to avoid strong pressure impacts, pipe lines must be deflated from the utilization points at the highest and farthest sections.

4. Installation must be tested at a pressure 1.5 times higher than that of pipe operation pressure during 30 minutes. Operation pressure describes maximum operation pressure at 20 °C and indicated on all of the pipes.

5. During this time, no pressure fall in manometer and impermeability should occur.

6. If pressure drops in the manometer which test is observed, this means leakage occurs and leaking pipe line must be checked and if necessary replaced.

POINTS TO BE CONSIDERED ON PEX PIPES INSTALLATION

- No installation should be done at temperatures below 0 °C. For installation, pipes must be stored at ambient temperature (20°C).

- PEX pipes must not be exposed to sun light.

- Corner conditioner must be used in the bends of 90 °C in the inlet and exists of ground concrete. Corner conditioners prevent cracks and leaks by balancing the expansion of pipes.

- Pipes must be installed tightly, and a tolerance of 10 mm should be reserved lengthwise in every 1 meters.(When temperature difference of 70 °C are taken into account)

- PEX pipes must be protected against external impacts.

- No air gaps should remain between grout concrete and pipe in the ground installations. Since this situation will form a heat barrier, ambient heat efficiency will decline.

- In order to connect PEX pipe to radiator at a 90° angle, jaw side of the inlet valves must face towards down. In case of jaw side facing towards wall of inlet valve, since angle will be 180°, a tension occurs in the pipe and so, cracks and bursts may happen in the emerging weak points.

- When sheathed pipes are laid down, sharp turns must be avoided. Otherwise, sheathing of new pipes will not be possible in pipe replacement.

- In order to protect Pex pipe system from freezing, the water must be discharged in the idle piping systems.

- Styrofoam density must be 16-18 gr/cm3 in ground installations, if load amount is heavy on the ground, then it must be 20-22 gr/cm3 density. In the normal floors, Styrofoam thickness must be 20 mm and in the soft ground such as soil, it must be 40 mm and Styrofoam must be covered with a plastic canvas.