Application Techique

Extruder welding method is used for joining PE and PP panels for manufacturing final products. The procedure includes preheating using welding rod made of the same class raw material and spreading the molten state material on the welding area at a certain speed by applying pressure.

Aspects to be Considered During Application

Welding operation shall not be performed under 5 centigrade degree or if such is inevitable, measures shall be take to ensure that the welding environment reaches to a minimum temperature of 5°C.

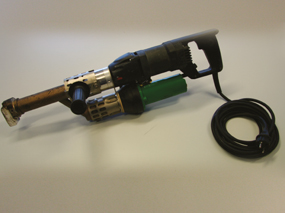

Welding Extruder

Welding Extruder Welding T

Welding TMaterial to be welded and the welding rod shall be made of identical class polymer and diameter of the welding rod shall be 3-4 mm.Surfaces to be welded shall be clean, irregularities which may impair welding quality such as oil, dust, soil etc. shall be cleaned prior to the welding operation.

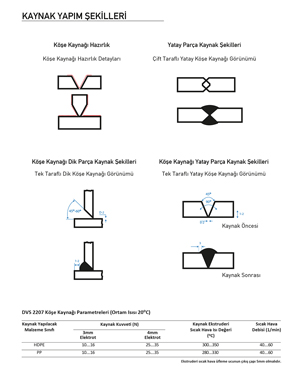

Welding surface shall always be scraped during surface preparation stage and oxidized layer shall be removed. Beveled welding groove shall be established.

Scraper - Reamer

Scraper - Reamer  Scraper - Reamer

Scraper - Reamer Manual welding extruder shall always be kept at an angle of 45° to the welding surface.

Pre-welding shall be performed by using 4 mm welding rod for large and deep welding operations then it shall be followed with second or if required, third welding operations using welding rods with suitable size and shape. Welding zone shall cool down before applying the succeeding welding layer.