Fırat, having broken the world monopoly by producing a PE 100 pipe, withstanding a pressure of 16 bars, with 1200mm diameter and 109.1 mm wall thickness, to be used within the scope of "Bosporus Crossing Project", and carrying water to the European side of Istanbul, has created another “first” in its country by producing a 500m long pipe.

Under ENKA's contracting, the usage of the PE 100 pipes to supply drinking water to the city by the purification of the sea water in Libia, with the diameter of 1400mm, wall thickness of 55 mm, withstanding a pressure of 6,4 bar, have been produced as 6 pieces with a length of 500m and has reached a total length of 3000m.

Mehtap Uluceviz, Fırat Plastic Infrastructure Marketing Manager, having stated that the single part pipe production is in the hands of the North European countries, has said “We are producing these type of pipes for the first time in our country”. ENKA, the contractor of the project in Libia, has initially applied to this company. Afterwards, they have shared the project with us. Within a very short period of time, we have engaged into a hard work together with our engineers and workers. Actually since 1990, when the PE 100 has started to be used in the world, as Fırat we are using this raw material. Especially with this Melen Project, we have proven to the world as to what we could do regarding this issue. And by sharing this with ENKA, we have shown our technology and power and by develoing our knowhow we have received this job. One thing, which made us very happy, was to break the single body pipe monopoly of the Northern countries in this region. They are no longer alone.".

Each one of the pipes, with a height of 500m, is weighting 110tons.

Mehmet Erdoğdu, Technical Infrastructure Manager of Fırat Plastic stated the following: "Long pipes enables to implement less welding, and enables the installation of the distances without any gap and in a short period of time. The fact that the pipes have less connecting points assures that the hydrolic pressure losses are kept at the minimum level. Due to the fact that these pipes had to be transported by taking them over the sea, necessitated the building of a mobile production plant at the coast of Büyükçekmece. We have completed this plant in a short period of 15 days. And our production continued for 30 days in total. We have carried the pipes, which we have produced, with the running wheel system, developed at our R&D Department.

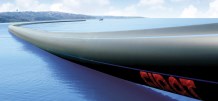

Dardanelles Strait Crossing

6 pieces 500 meter long pipes have been carried to Libia over the sea by making them swim along with the vessel, departing from the Büyükçekmece coast. During the crossing, the Dardanelles Strait has been closed to traffic due to safety reasons.