Technical Informations / Installation Procedure

The installation rules of PE pipes are identified in the ATV-A 127 and EN 805 standards. After welding the pipes outside the channel, they can be descended inside the channel. In here, it is important that channel digging should be narrow.

- Pipes must not be crushed in any way.

- The pipes that are damaged during handling or storage (bruised with tools with sharp tip or materials like stone) must definitely be avoided.

- Definitely there must not be deposited underground water or rain water within the channel. (If water deposited in the channel, water must be drained with the help of a pump.

- Non-adhered sand, gravel, mixed-grain, sand and gravel can be used as channel filling material.

- Channel depth must be minimum 70-80 cm.

- If digging earth is available to filling, pipe can be laid down directly on the channel ground without requiring bedding. If digging earth is not available for filling (stony, watery etc.) channel dept must be increased and bedding should be done with dry filling material (e.g. sand).

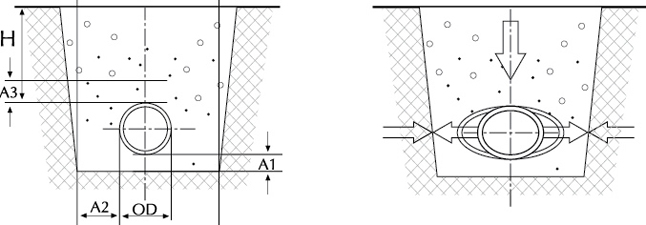

- The bedding thickness to be done must be minimum A1 = 100 mm + 1/10 DN. With the help of a light-working compactor, bedding material must be compacted until a 95% resistance is achieved.

- Pipe side fillings casted at a thickness of A2, 30 cm and they must be compacted with the help of light compactor at a rate of 92-95%. This operation must be continued until it passes 30 cm over a pipe in every 30 cm.

- Filling process must be completed after it passes A3 = 30 cm over pipe by compacting with a middle-force compactor.

CHANNEL PIPE IN SETTLEMENT