Pipe Features

Advantages of Tunnel Type PVC Drainage Pipe and Fittings

- With PVC rawmaterial high resistance to underground acidic and basic liquids is ensured.

- Horseshoe form, vertical groove of the internal and external structure ensures resistance to external forces.

- It can be installed easily with its bell mouth structure and flat base.

- It is lightweight and does not require additional construction vehicle for handling.

- Integrated socket shaped section enables quick mounting.

- Since its base is flat flow and flow rate of water increases.

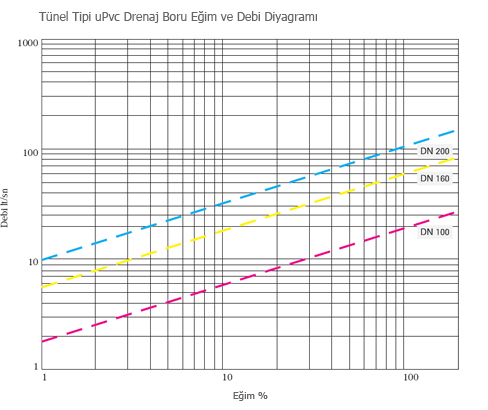

- It can be manufactured in 100 mm, 150 mm and 200 mm diameters with a length of 6 meters as perforated or non-perforated.

- With 220° perforate angle, the water does not return to the ground and high suction flow rate is realized.

- Since it is easy to install, it does not require trained personnel and demanding workmanship.

- Since all fittings have specially designed latch connection, separation does not occur at joints.

- It is durable against sun rays and external effects.

- Pipes manufactured as non-perforated can be used as collector.

Standards Concerning Technical Features of Tunnel Type PVC Drainage Pipe and Fittings

Tunnel Type PVC Drainage Pipe and Fittings: DIN 4262-1, TS 9128 Chemical Resistance Standard: ISO TR 10358

PVC Rawmaterial Standard: DIN EN 1905

TSEK

| Product Code No | Nominal Diameter | Diameter (d) mm ±2.5 | Height mm ±2.5 | Profile Width mm | Number of perforation holes piece/m | Cross-section Area cm2 | Perforated Area› cm2/m | Length (L) Spigot/m | Length (I) Without spigot/m |

|---|---|---|---|---|---|---|---|---|---|

| 7324000254K | 100 | 110 | 110 | 10.15 | 396 | 82 | > 55 | 6.28 | 6.22 |

| 7324000318K | 150 | 160 | 160 | 14.66 | 408 | 182 | > 60 | 6.28 | 6.18 |

| 7324000381K | 200 | 210 | 210 | 16.06 | 360 | 318 | > 80 | 6.28 | 6.16 |